Waste Gas Utilization

Gas processing, conditioning and gas enrichment

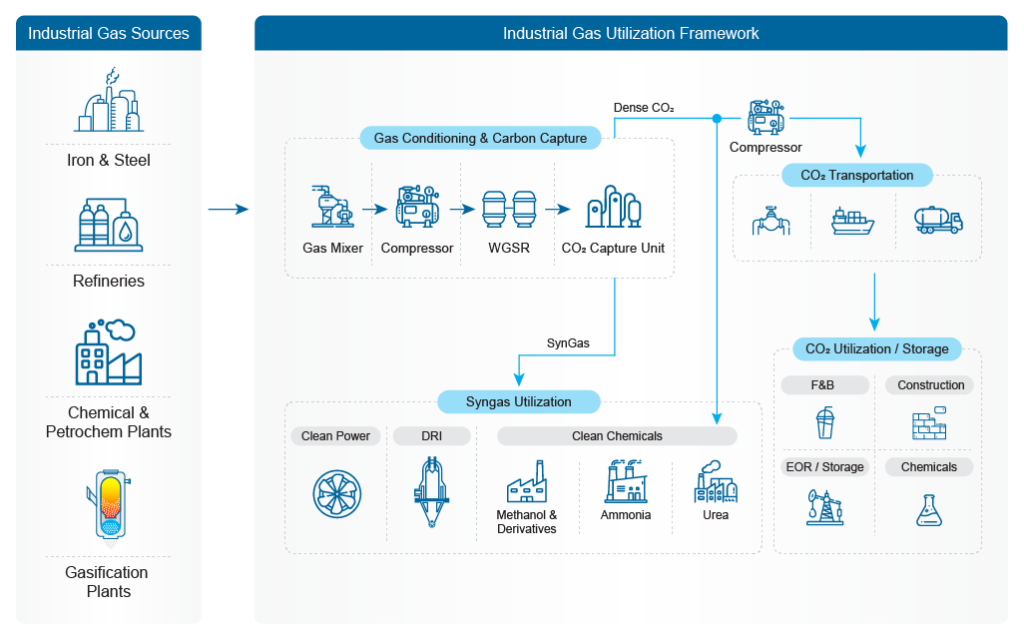

Industrial process gases generally have a significant content of energy-rich components like CO, CH4 and H2, apart from CO2 and N2. However, current industrial practices are not designed to fully exploit the value/energy content of these gases. These gases are used either as low-value fuels in captive power plants, reheating furnaces or stoves or flared, leading to lower energy efficiency and higher GHG emissions.

Dastur Energy uses its IP and process know-how to design waste gas conditioning, enrichment and utilization systems suitably integrated with the main process units, thus providing a pathway for improving overall energy efficiency and significantly reducing CO2 emissions. Value creation is also possible by converting waste gases into high-value products such as hydrogen, DRI, methanol etc., in an energy-efficient and environmentally sustainable manner instead of using them merely as low-value in-plant fuels.

The key components of our solution include:

-

Appropriate and calibrated conditioning of the industrial process gases to enhance the energy content and desired gas composition, leading to optimized reactor sizing and steam & catalyst consumption

-

Designing suitable CO2 capture schemes with the appropriate source, scale and technology – optimizing the CO2 concentration and capture point through appropriate gas conditioning

-

Utilizing energy-rich syngas for the production of value-added products.

-

Appropriate recycling schemes to improve overall energy utilization and integration.

Technology Pillars

-

Industrial Carbon

Capture -

Carbon Dioxide to Value -

Hydrogen -

Green Molecules -

Waste Gas Utilization -

Gasification