Gasification

Petcoke, coal, biomass, plastics, wastes based net-negative gasification

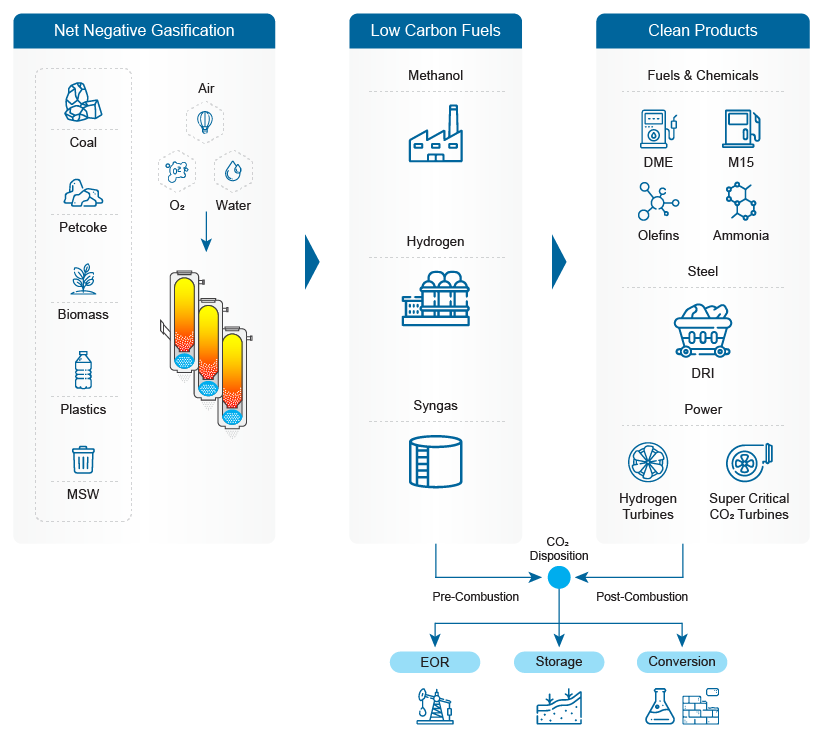

The gasification of solid fuels like coal and biomass or wastes like petcoke, plastics and MSW can be used to power clean energy systems at scale. Gasification produces syngas, which is a mixture of CO, CO2 and H2; syngas can be conditioned to achieve the CO:H2 ratio required for the desired portfolio of clean and economically attractive downstream value-added products. Along with low-cost carbon capture on dense CO2 streams(99%+ purity with high partial pressure), gasification provides a pathway to cost-effectively decarbonize the industrial, power, fertilizer, and chemical sectors. The appropriate blending of feed materials such as petcoke, coal, biomass, plastics and MSW can make gasification a net-negative emissions technology.

Dastur Energy is helping clients across the world by designing integrated and business-driven gasification-based solutions with integrated carbon capture. These enable our clients to meet their multiple strategic goals, whether it be the conversion of waste petcoke to value-add products or sourcing of dense stream CO2 at competitive costs for EOR, or providing clean fuels for use in kilns & furnaces. Some of the key ways in which our clients benefit are:

-

Concept and design of techno-economically viable gasification projects integrating feedstock supply chain design & blending, gas conditioning, downstream units and appropriate carbon disposition mechanisms & infrastructure.

-

Expertise in various gasification technologies and fuel engineering – enabling clients to overcome the challenges of different feedstocks, such as high ash coal in India, lignite in Indonesia, plastics and biomass in the US, and petcoke all over the world.

-

Licensing and basic engineering of economically viable gasification solutions based on fluidized bed, entrained flow, moving bed or allothermal gasification technologies.

-

Formulating poly-product portfolios consisting of marketable chemicals, balanced by utilities such as hydrogen and power, providing projects with operational flexibility

-

Stay ahead of the regulatory curve by using gasification to convert wastes into valuable marketable products

Technology Pillars

-

Industrial Carbon

Capture -

Carbon Dioxide to Value -

Hydrogen -

Green Molecules -

Waste Gas Utilization -

Gasification