This fusion enables us to translate breakthrough concepts into bankable, scalable industrial solutions – not pilots that remain in laboratories.

Applied R&I for Solving Today’s Industrial Challenges and Activating Tomorrow’s Systems

Our approach is rooted in advancing technology through applied Research & Innovation (R&I) to unlock materials and energy abundance – all at the lowest cost and CO2 footprint.

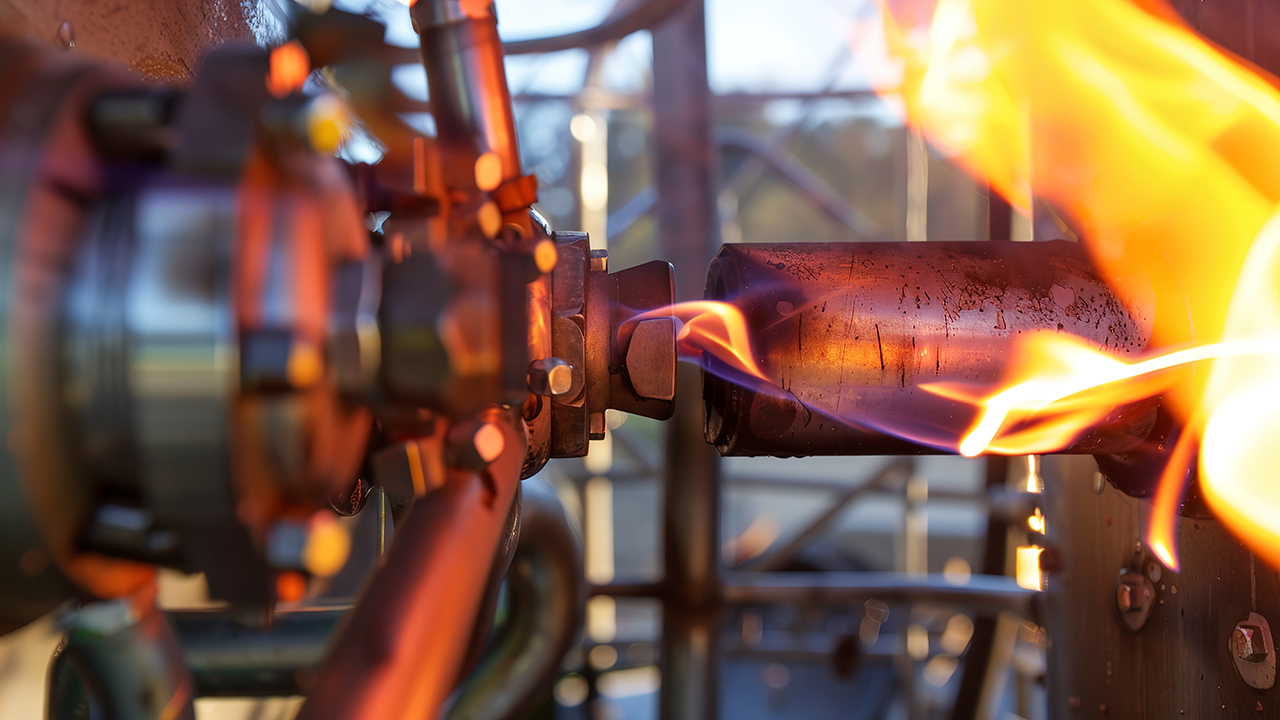

DIL’s industrial solutions are based on the fundamental principles of engineering, multi-scale process modeling, fluid dynamics, mass & energy balance, high temperature thermochemistry and rate kinetics coupled with data analytics, process economics and operational expertise.

Innovation Through Partnership

At DIL, we believe that the future is built together. We work with global technology leaders, academic institutions, and industrial partners to validate and scale technologies in live industrial environments.

DIL team has partnerships with or in the recent past has collaborated with the following institutions/organizations:

Thought Leadership, Peer Recognition

DIL researchers actively contribute to global discourse through papers, patents, and conference keynotes. From prestigious journals to high-impact summits, we share insights that shape the direction of industrial innovation and policy. Explore our growing archive of published research and thought pieces.