OUR APPROACH

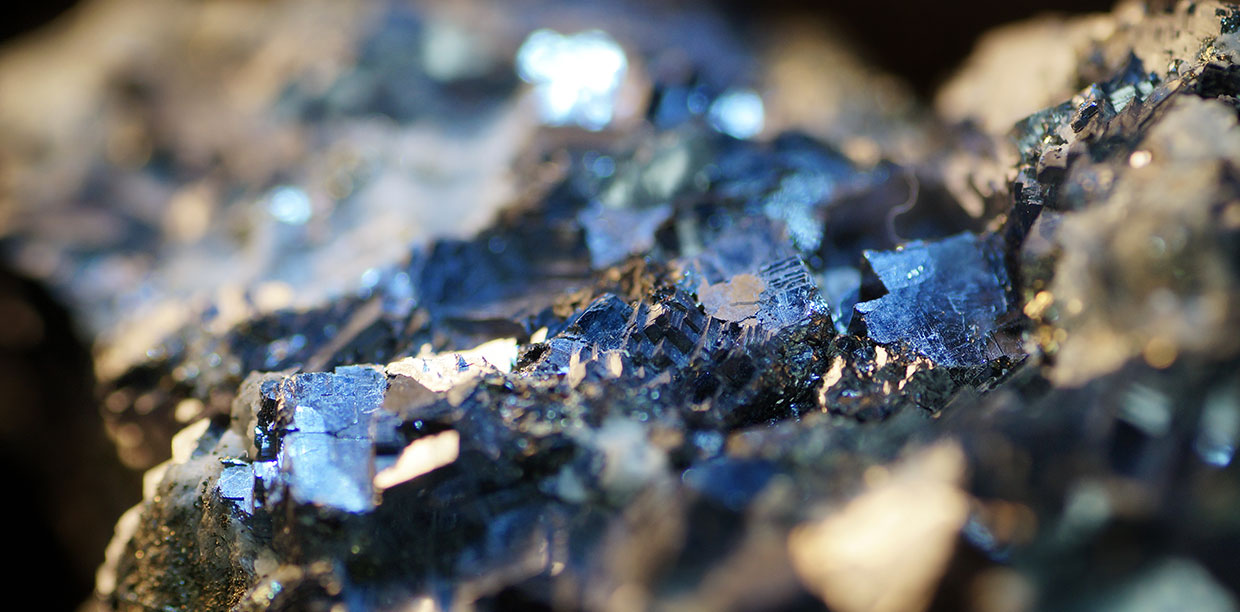

We deliver integrated solutions across the entire critical minerals value chain—from resource extraction to refining, recycling, and market delivery. Our expertise spans primary pathways (mining, beneficiation, refining) and secondary pathways (recycling, recovery, circular processing), enabling clients to reduce import reliance, hedge against price volatility, and build truly sustainable materials economies.